Henry J. Kaiser’s environmental stewardship

Since the 1940s, Kaiser Industries and Kaiser Permanente have a long history of employing technology to reduce waste and promote renewable energy.

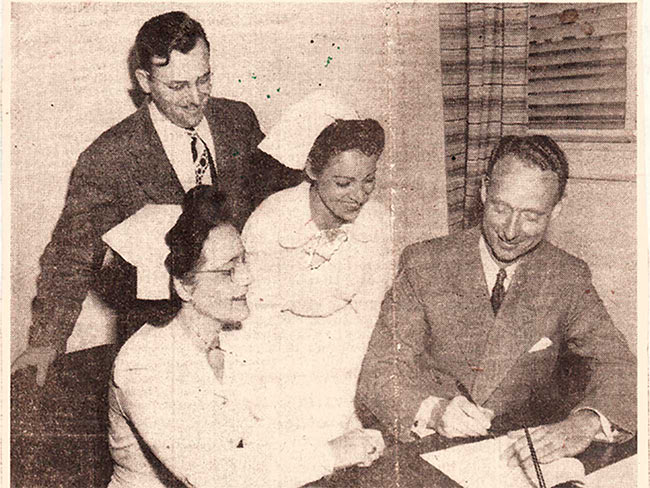

Newspaper ad from Fontana steel plant about reduced emissions, circa 1956

“Being environmentally aware is more than good citizenship: if approached with a long-term perspective, it brings efficiencies, saves money, and improves competitiveness. For Kaiser Permanente ... environmental stewardship is a core business tenet, and it started in the beginning.” - “The Green Standard,” Fall 2008; Transforming Your Enterprise (Hewlett-Packard corporate magazine)

We couldn’t have said it better.

Henry J. Kaiser and his numerous industries – including the health plan and hospitals – have often been models of environmental stewardship. Although Henry J. Kaiser was no tree hugger, and on occasion his massive construction projects took shortcuts that today might make us cringe, he was an ethical leader who valued efficiency and frugality.

Here are several examples of Kaiser Industries and Kaiser Permanente environmental practices over the decades.

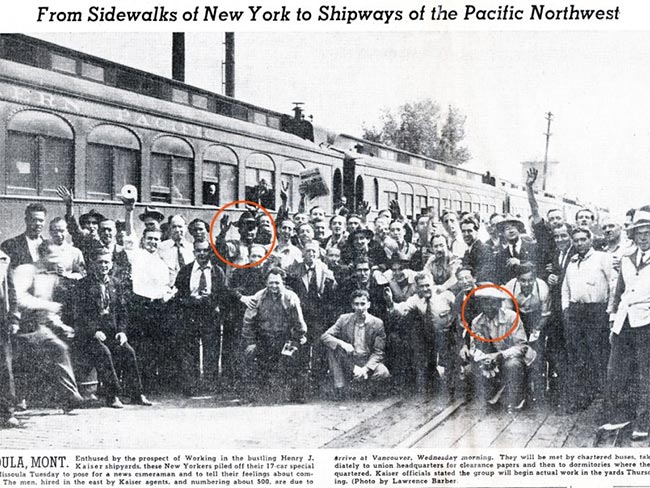

1941

Environmental controls at Fontana Steel:

"One problem that was not given extra thought at the start but which became more and more burdensome was the matter of air pollution control. All of the original ovens and furnaces were designed with the same emission controls as the newest steel mills in the East, but that proved not to be enough in the smog-conscious Southern California. However, as troublesome and costly as the problem proved to be, his engineers and operators knew they would always have Kaiser's backing in their efforts to be leaders in the field of air pollution control."

— Heiner, A. P. (1991). Henry J. Kaiser, Western colossus: An insider's view. San Francisco: Halo Books.

1959

“Kaiser Industries Seek to Enrich Communities,” Christian Science Monitor article on Fontana Steel plant; June 12, 1959

For people anywhere near the steel mill, one apprehension formed the question, “Will it make smog?” Henry Kaiser laid down a rule when the plant was started: “Don’t make it a nuisance.” His engineers believe they have carried out the directive. Nobody who travels out the San Bernardino Freeway from Los Angeles on a smoggy day can help wondering about those high stacks behind the eucalyptus trees that mark the steel mill. But looking closer, he grants that precious little smoke is visible.

From the start, Kaiser Steel built $5,000,000 worth of air control devices. It put electrostatic precipitators on the blast furnaces. Then it developed a $30,000 laboratory to study, among other things, the effects of air contaminants on plant life. Researchers of Kaiser Steel get leaf samples from 79 different places; they operate three greenhouses in the pattern of the smoke. One man puts it this way, “We’re working to be part of the answer instead of part of the problem.”

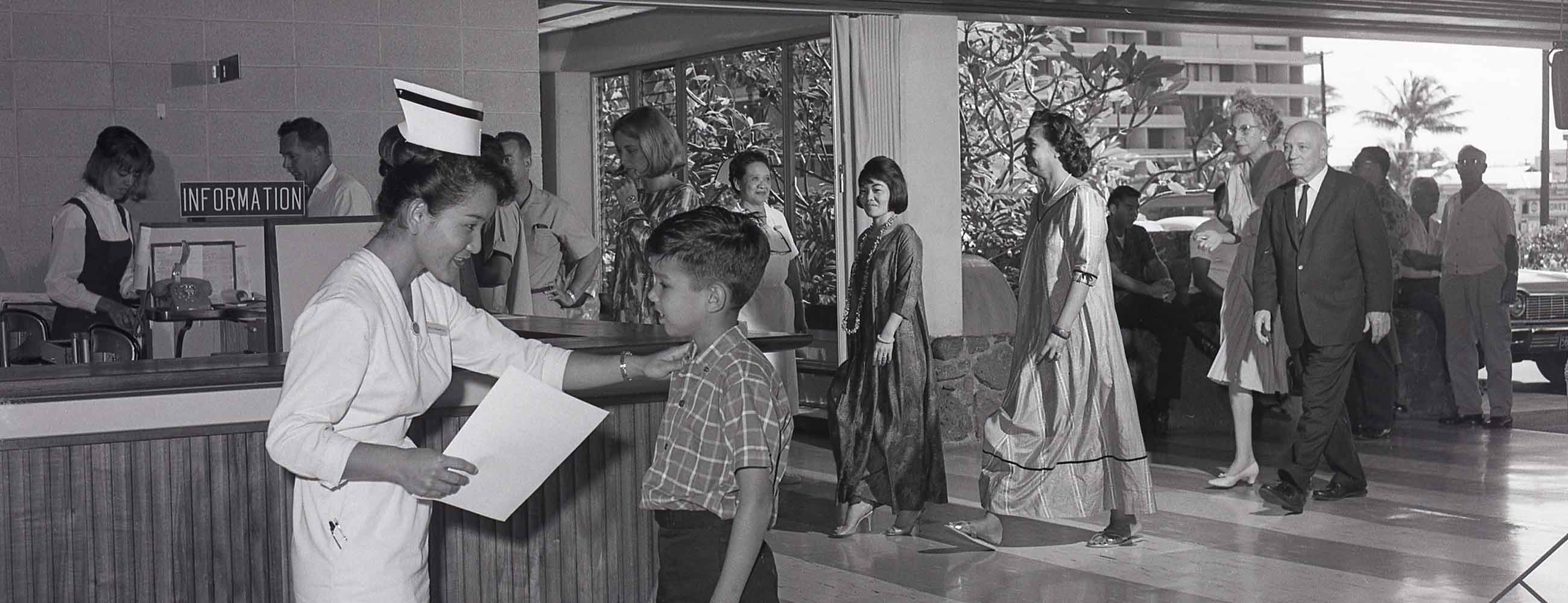

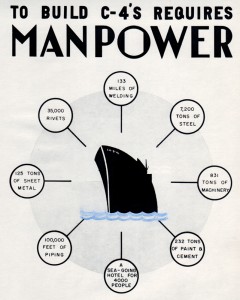

Over in Honolulu, Mr. Kaiser’s approach is the same. His plans for a $12,000,000 cement plant in Oahu stress that the operations will be “dust-free.” Always a stickler for factory good housekeeping, Mr. Kaiser says he will do nothing that will cloud the island’s tropic skies.

1963

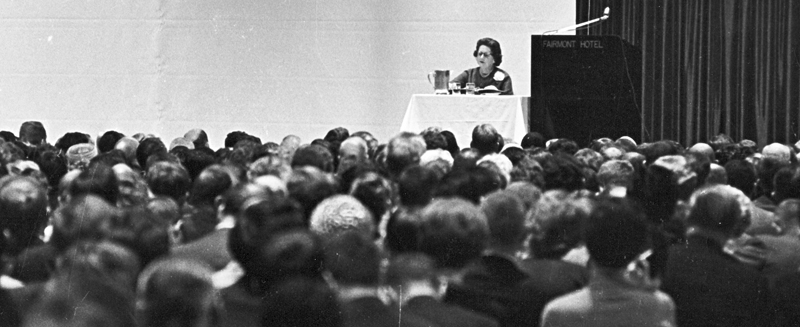

“Kaiser Sponsors Talks on Scientific Dangers,” Planning for Health, Vol. 8, No. 4, December 1963

The largest audience in its 7-year history attended the symposium sponsored by Kaiser Foundation Hospitals and Permanente Medical Group for the Bay Area medical community. The topic of the meeting, "Man against Himself," was keynoted by Rachel Carson, biologist and writer. Her book Silent Spring drew the attention of Americans to the destructive effect of poisons being sprayed to kill insects.

Other distinguished authorities discussed, during the two-day session, various other ways in which man threatens to destroy his basis for life: tobacco and its relation to cancer and heart disease; the part played by social progress, with its pattern of inactivity and overeating, in a rising incidence of heart disease; the hazards of radiation.

1978

“HEW funds solar energy project” (Santa Clara, Calif.), KP Reporter, May 12, 1978

Kaiser Permanente recently signed a contract with the federal government for a solar energy demonstration project at our Santa Clara Medical Center. The $203,000 project should be operational by early 1979. When operational, it is expected that 30% of the hot water used throughout the medical center will be heated by solar energy, which would mean a saving of 935 million BTUs per year.

Our Redwood City Medical Center has been using solar energy on a much smaller scale for the past year or so. Although built in-house by Engineering staff with limited materials, the Redwood City effort has been effective in lowering the cost of utilities. (When it opened, the project was one of the largest solar installations at a health care facility in the United States.)

So, what has Kaiser Permanente done for Mother Earth lately? Plenty.

Half the energy it uses in California will come from renewable sources by next year when solar and wind energy projects under construction are completed. Other efforts help improve previous programs – like phasing out furniture treated with fire-retardant and stain-resistant chemicals with healthier choices. And Kaiser Permanente has created the industry’s first Sustainable Food Scorecard, helping improve the environmental profile of the goods we purchase.

Kaiser Permanente — thriving with Earth Day since we began.